Why is stainless steel strip often used to make cables

source:www.tzjbxx.cn | Release time:2025年06月25日1、 Excellent physical and mechanical properties

High strength and tensile strength

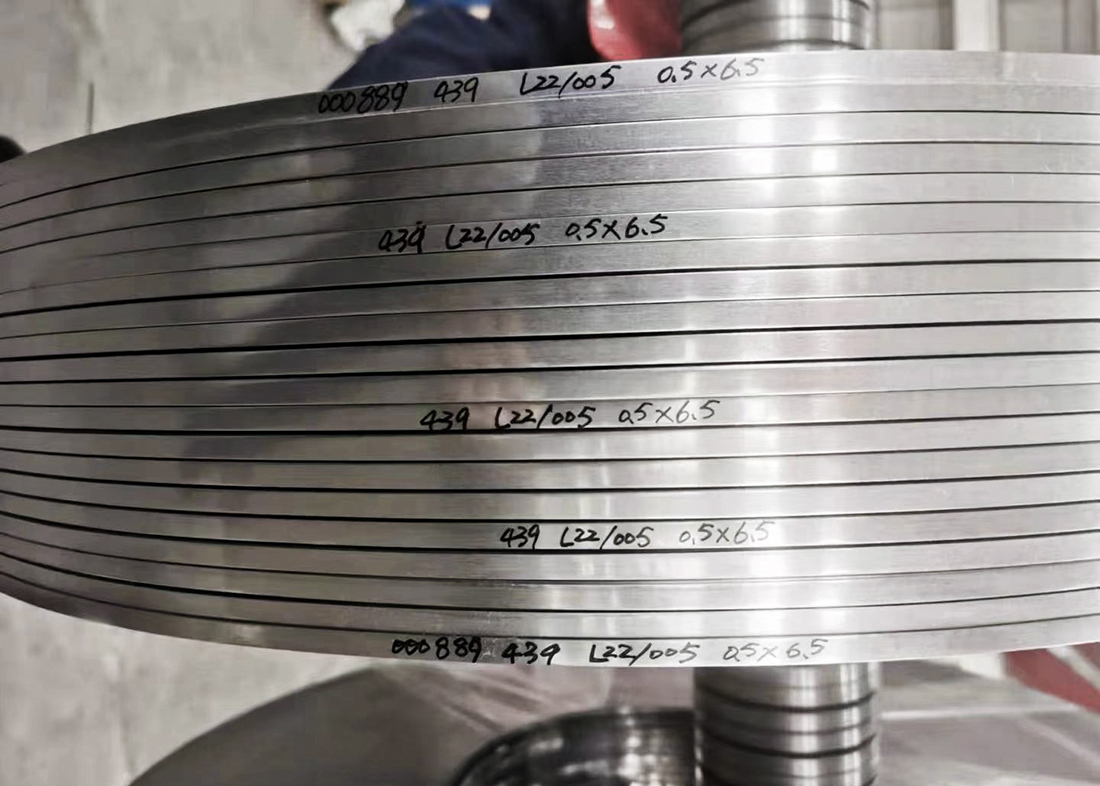

The tensile strength of stainless steel strips (such as 304, 316 austenitic stainless steel) can reach 500-800MPa, much higher than ordinary carbon steel (about 300-500MPa). They can withstand the traction force during cable laying and the mechanical stress during long-term use, avoiding damage to the cable structure caused by tensile deformation.

Case: In the armor layer of high-voltage transmission cables, stainless steel strips can resist soil pressure and mechanical external forces during underground laying, protecting the internal insulation layer and conductors.

Good flexibility and processability

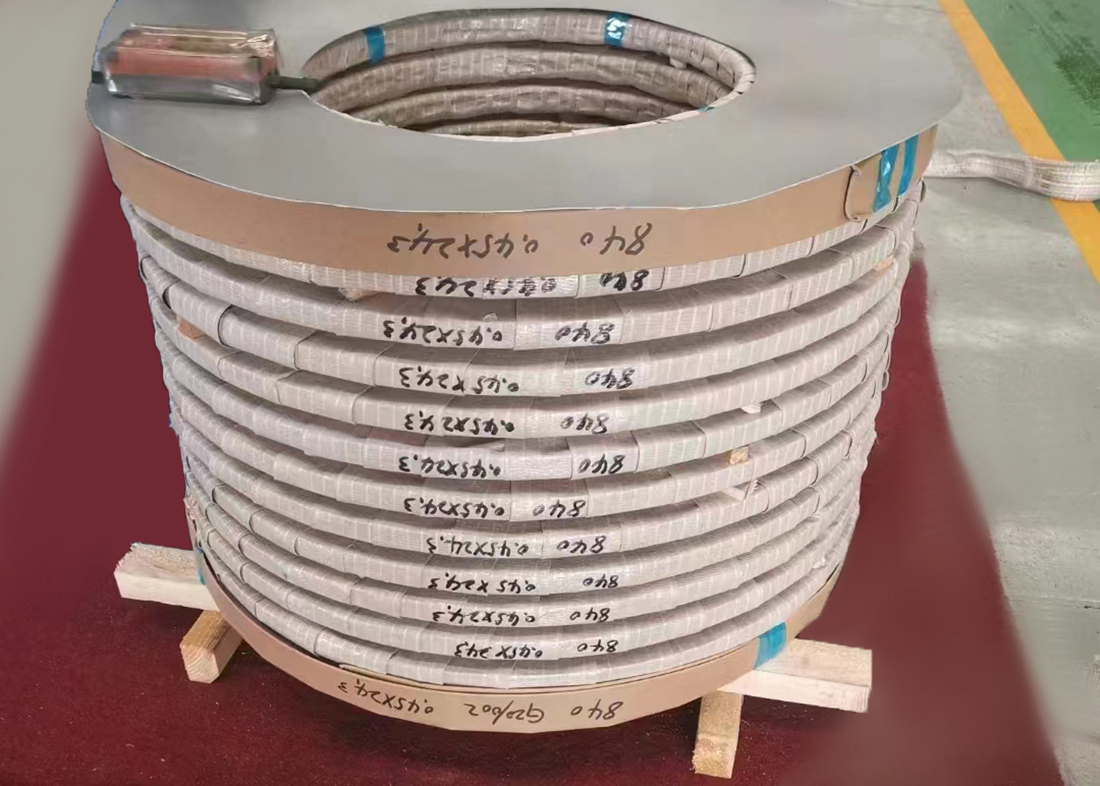

The thickness of cold-rolled stainless steel strip can be up to 0.02mm or less, and it can be easily wound into cable armor or shielding layers of various diameters, and it is not easy to break during the processing. For example, precision stainless steel strips can be used for the shielding mesh of miniature cables, meeting the compact installation requirements of electronic devices.

2、 Excellent corrosion resistance and environmental adaptability

Corrosion Resistance

The chromium (Cr) element in stainless steel strips forms a passive film, which is resistant to acid, alkali, salt, and humid environments, especially suitable for highly corrosive scenarios such as marine engineering and chemical enterprises.

Comparison: Ordinary steel strips are prone to rusting in humid environments, causing damage to the cable insulation layer, while 316L stainless steel strips have a service life of more than 5 times that of ordinary steel strips in seawater environments.

High and low temperature resistance performance

Stainless steel strip can maintain stable performance within the range of -200 ℃ to 600 ℃:

Low temperature scenario: such as the armor layer of freezer cables to avoid low-temperature embrittlement;

High temperature scenario: Cables near industrial furnaces to prevent softening or oxidation due to high temperatures.

3、 Excellent electromagnetic shielding and grounding function

Electromagnetic shielding effect

The metal conductivity of stainless steel strip (conductivity about 1/20 of copper) can form Faraday cage effect, effectively blocking external electromagnetic interference (such as cables near high-voltage substations and communication base stations), ensuring the stability of signal transmission.

Application: Stainless steel tape can reduce signal attenuation and crosstalk in the shielding layer of computer cables and communication cables.

Grounding and lightning protection performance

Stainless steel strip, as the grounding conductor of cables, can quickly guide away induced charges or lightning currents, reducing the risk of equipment damage. For example, the stainless steel armor layer of outdoor overhead cables can be connected to the grounding grid to form lightning protection.

4、 Meets industry standards and safety requirements

Flame retardant and fire-resistant properties

Stainless steel strip itself does not burn and does not release toxic gases in a fire, meeting the flame retardant standards of cables (such as IEC 60332). In scenarios with high safety requirements such as firefighting and subway, stainless steel armored cables are the preferred choice.

Environmental and Health Standards

Food grade stainless steel strips (such as 304, 316L) have no heavy metal precipitation and can be used for cables in food processing plants to avoid contamination risks; Cables in the medical field often use stainless steel shielding layers to meet cleanroom standards.

5、 Cost effectiveness and service life ratio

Long term cost advantage

Although the procurement cost of stainless steel strip is 20% -50% higher than that of ordinary steel strip, its corrosion resistance and wear resistance can extend the service life of cables by 2-3 times, reducing replacement and maintenance costs. For example, using stainless steel armor for offshore wind power cables can reduce maintenance frequency.

Lightweight and Space Optimization

The density of stainless steel strip (about 7.9g/cm 3) is lower than that of copper (8.9g/cm 3), and it is lighter in weight under the same strength. It is suitable for cables used in high-altitude or mobile equipment (such as elevator cables and robot cables), reducing load pressure.

6、 Example of typical application scenarios

Ocean engineering: The stainless steel armor layer of submarine cables resists seawater corrosion and deep-sea pressure;

Chemical industry: Heat tracing cables for pipelines transporting corrosive media are made of 316L stainless steel tape to prevent medium leakage and corrosion;

High rise buildings: Stainless steel tape armor is used for vertically laid power cables to enhance tensile and fire resistance performance;

In the field of new energy, the stainless steel shielding layer of photovoltaic cables is resistant to outdoor ultraviolet radiation and ozone aging.

【Related articles】

【Related products】

+

WeChat ID:www.tzjbxx.cn

WeChat ID:www.tzjbxx.cn

WeChat ID:www.tzjbxx.cn

WeChat ID:www.tzjbxx.cn

Add WeChat

Add WeChat

Contact us

Contact us

The phone

The phone